How Artificial Intelligence Predicts Failures and Enhances Maintenance Efficiency ?

Artificial Intelligence (AI) is revolutionizing the way industries approach maintenance by shifting from reactive to predictive strategies. Traditionally, equipment was serviced on fixed schedules or only after a failure occurred. This often led to unnecessary downtime, excessive maintenance costs, or even catastrophic equipment failure. AI changes that by enabling systems to predict issues before they happen.

Using historical and real-time data from sensors, AI algorithms analyze trends in temperature, vibration, pressure, flow rates, and other key indicators. By recognizing subtle patterns and deviations from normal behavior, the system can detect early warning signs of mechanical problems — such as bearing wear in high-pressure pumps, imbalance in rotating equipment, or loss of efficiency in energy recovery devices.

These predictive insights allow maintenance teams to act at the right time — not too early, not too late. This improves maintenance efficiency by reducing unnecessary interventions while preventing unplanned outages. In complex systems like desalination plants or industrial automation networks, AI-based maintenance strategies can drastically extend the life of critical components, reduce chemical and spare part usage, and improve overall system uptime.

Examples:

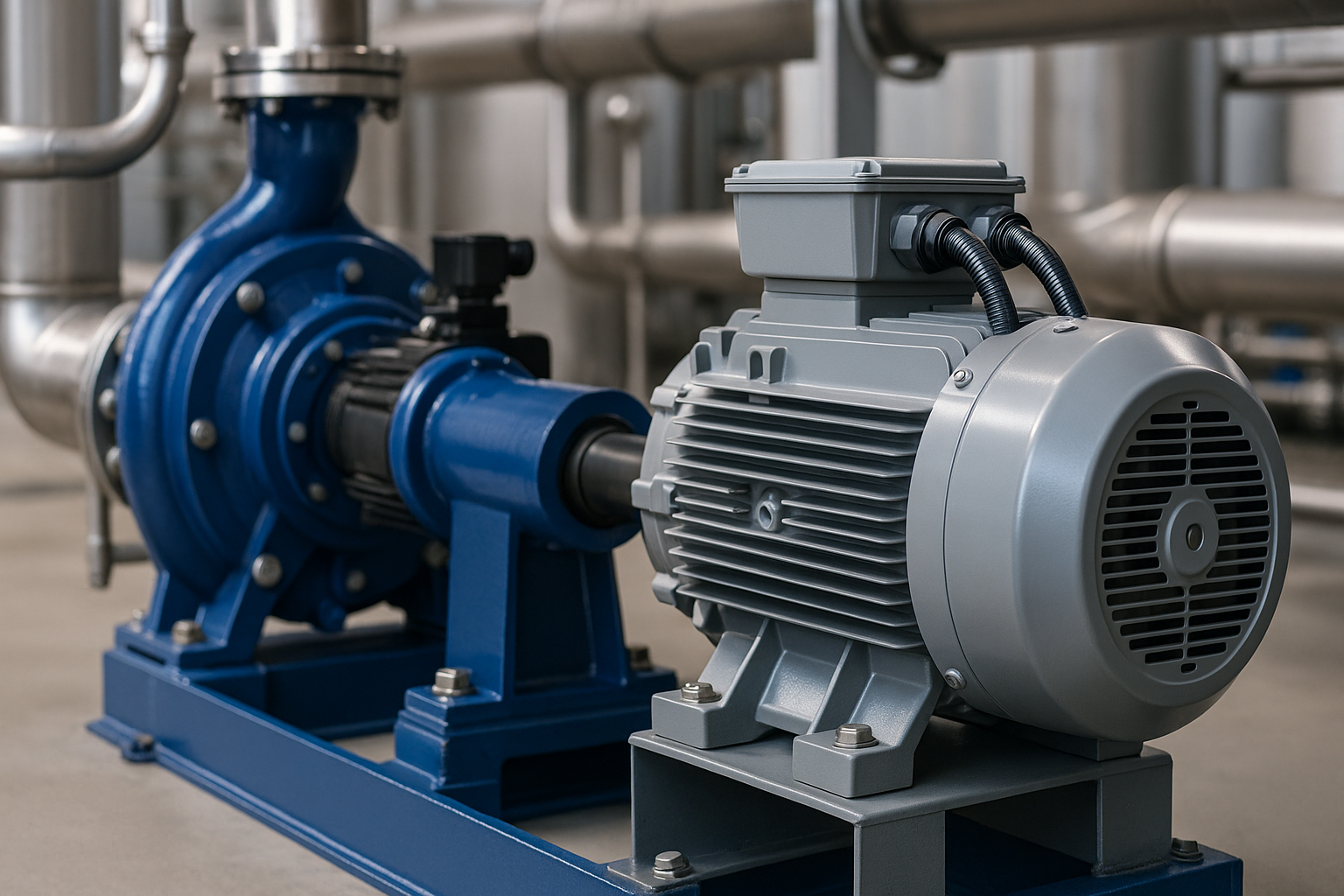

Early Detection of Bearing Wear in High-Pressure Pumps

High-pressure pumps are critical components in desalination and water treatment systems. Bearing wear often leads to overheating, vibration, and eventual failure. SensQuant uses AI-based vibration and pressure trend analysis to detect early signs of mechanical degradation. This enables maintenance teams to intervene before costly downtime or damage occurs.

Valve Health Tracking and Failure Prediction

Faulty control valves can disrupt entire processes or cause pressure spikes. Our AI models continuously analyze valve operation patterns, pressure fluctuations, and flow inconsistencies to identify signs of wear or actuator failure — often before operators notice a problem.

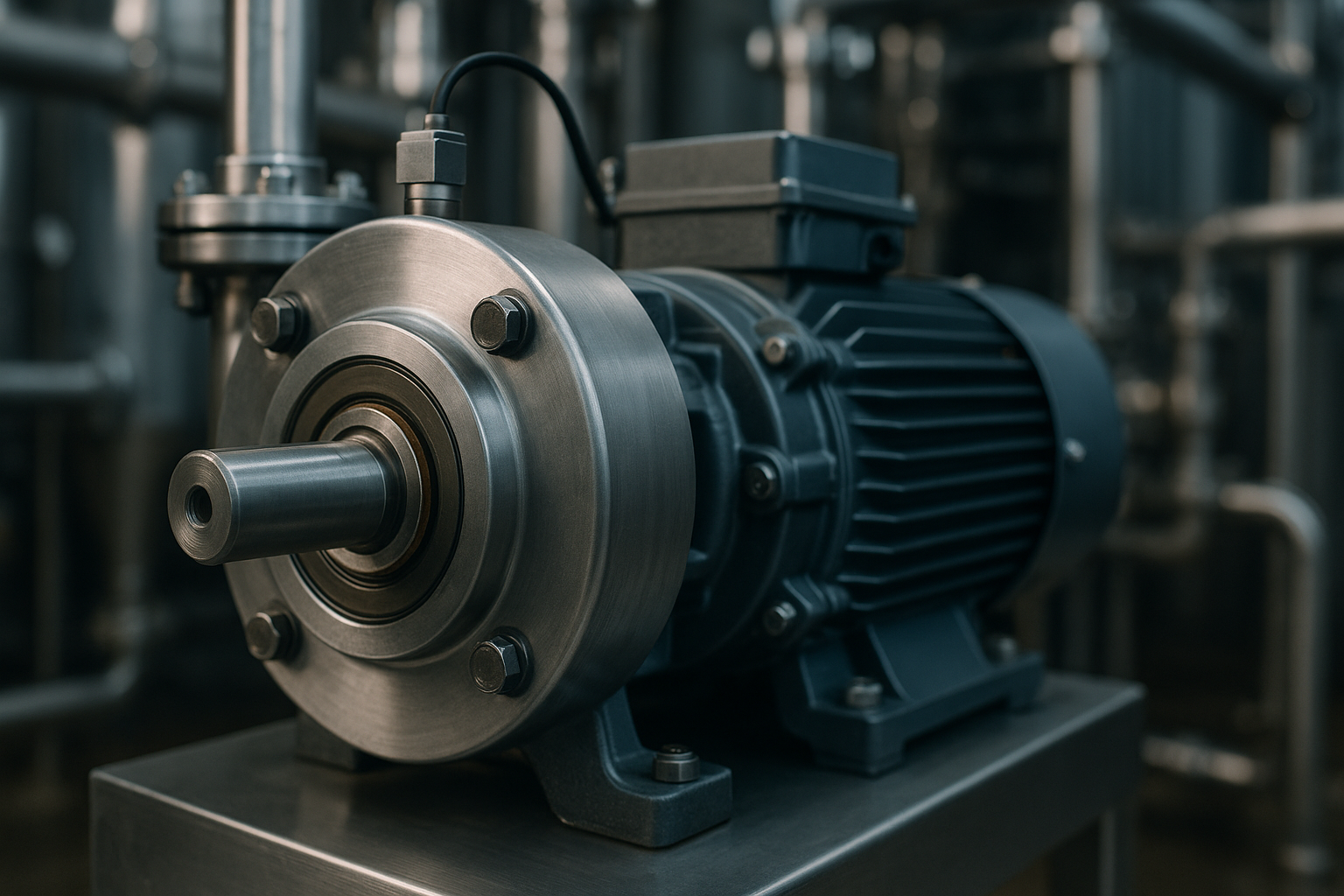

Pump Motor Overload & Thermal Stress Prediction

Overloading or frequent starts can degrade electric motors over time. Using current, torque, and thermal profile monitoring, SensQuant predicts when a motor is at risk of overheating or burnout, allowing for smarter operational adjustments and planned servicing.

Sensor Drift and Instrument Calibration Alerts

Even the best sensors degrade or drift over time, which leads to inaccurate process control. SensQuant tracks sensor outputs over long time windows and compares them to model-predicted values to flag potential calibration needs — improving data integrity and reliability.

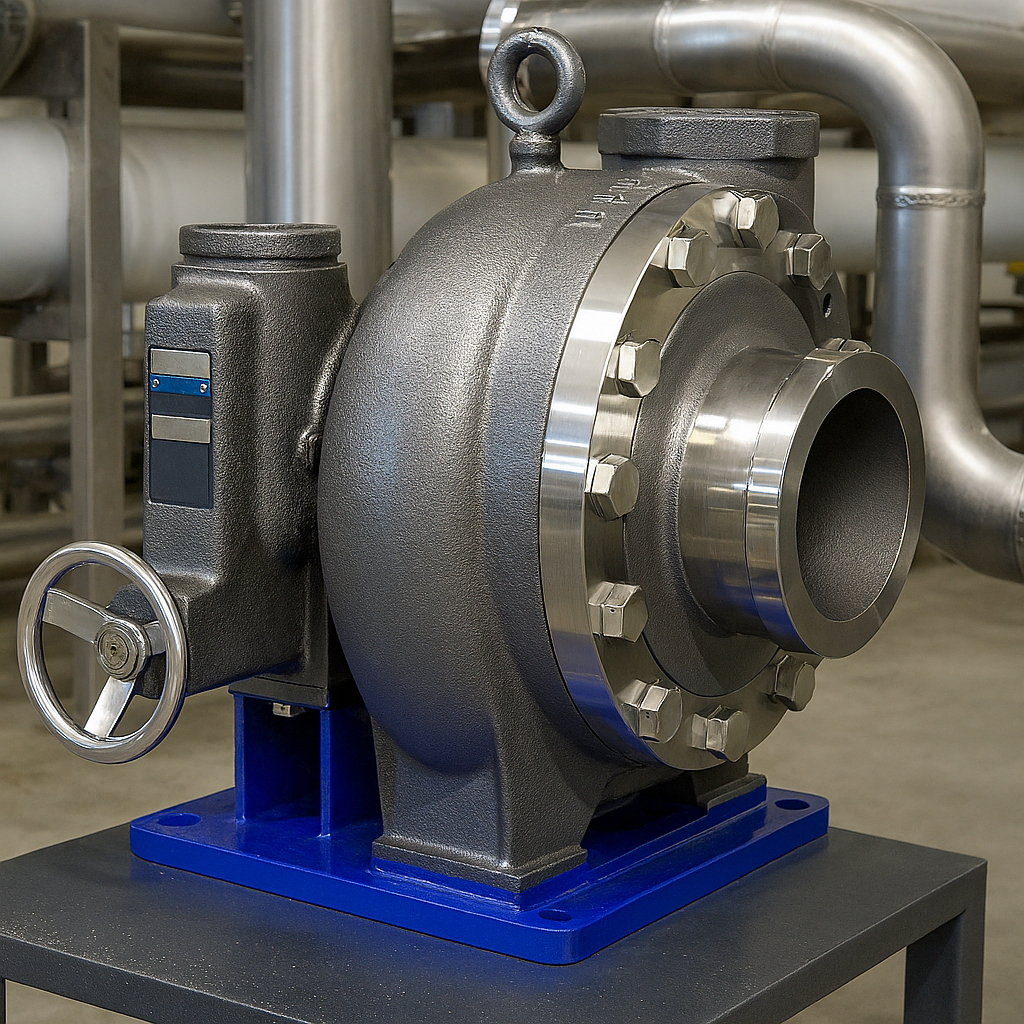

Anomaly Detection in Energy Recovery Devices (ERD)

Energy Recovery Devices are critical for reducing operational costs in desalination, but mechanical wear or flow imbalance can silently degrade their efficiency. SensQuant applies AI models to monitor pressure differentials, flow fluctuations, and vibration patterns to detect early signs of failure — such as rotor imbalance, internal leakage, or valve sticking. This enables operators to prevent energy loss and schedule interventions before ERD performance deteriorates.

The data is pulled from a data warehouse that can contain data from several studies and registers. Based on this, the backend of the data science tool does not store data. It instead stores filter and calculation rules for populations along with configurations of predefined analyses.

The tool enables various standard analyses as well as the creation of tables and specific analyses such as time-to-event analyses and Cox regressions. For approaches not included in the standard analyses, the tool provides a Jupyter notebook server with R and Python connected to the backend and data warehouse databases.